Want to hear more about the product range, features, delivery times or prices? Contact us and we will be happy to answer your questions.

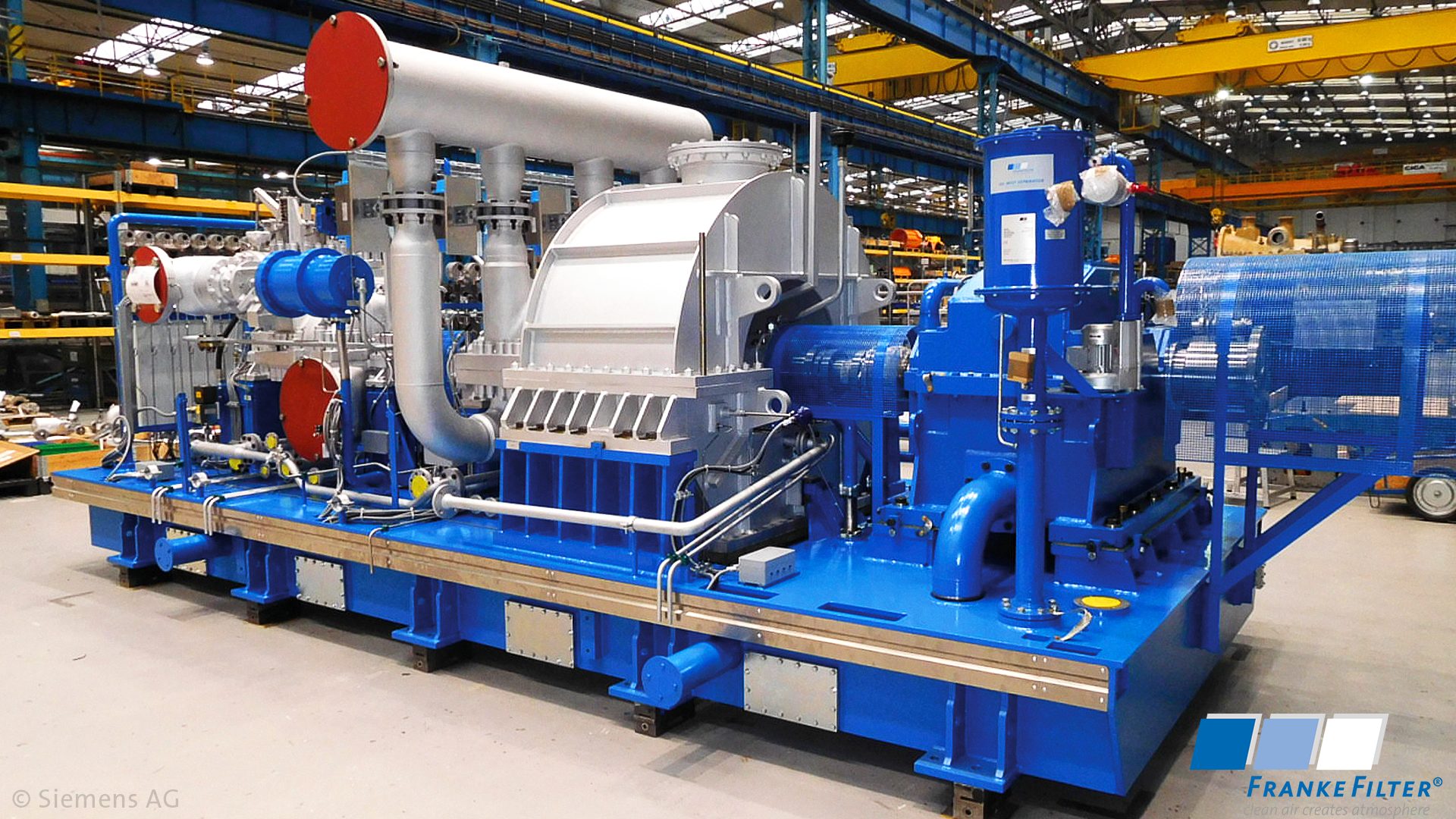

Franke Filter has strong expertise in Oil Mist separator systems. The products of the German company Franke Filter have a long maintenance interval of more than 30,000 hours and meet all the most general and special rules and regulations. They practically eliminate the loss of lubricating oil and prevent oil mist from entering the working air and the environment. Franke Filter’s biggest advantages are extremely effective oil mist separation, maintenance-free and customized, customer-specific equipment solutions.

Increasing environmental awareness and stricter standards for the cleanliness of exhaust air create new challenges for the industry. The German Franke Filter oil mist separator systems effectively prevents oil mist from entering the workspace and the environment. Franke Filter develops and manufactures oil mist separator systems considering exact, customer-specific requirements. Franke Filter’s decades of experience guarantee the best solutions – even for the most difficult applications.

The filtration results of the Franke Filter system are clearly better than the official emission values. The carefully designed design makes it easy to install the filters. All oil mist separator devices are manufactured and assembled at Franke Filter’s factory in Germany to order and are customized according to the customer’s needs.

Franke Filter’s versatile filter solutions are suitable for gas and steam turbines, water turbines, gas and diesel engines, turbochargers, generators, gearboxes, and other rotating engines.

When the back pressure has risen to the level of 100 mbar or the system has been in continuous use for 30,000 h. However, the filter elements must be changed at least every three years.

The devices are always manufactured according to the customer’s needs, so the delivery time is approx. 6 weeks. Filter elements immediately from stock.